About

Why?

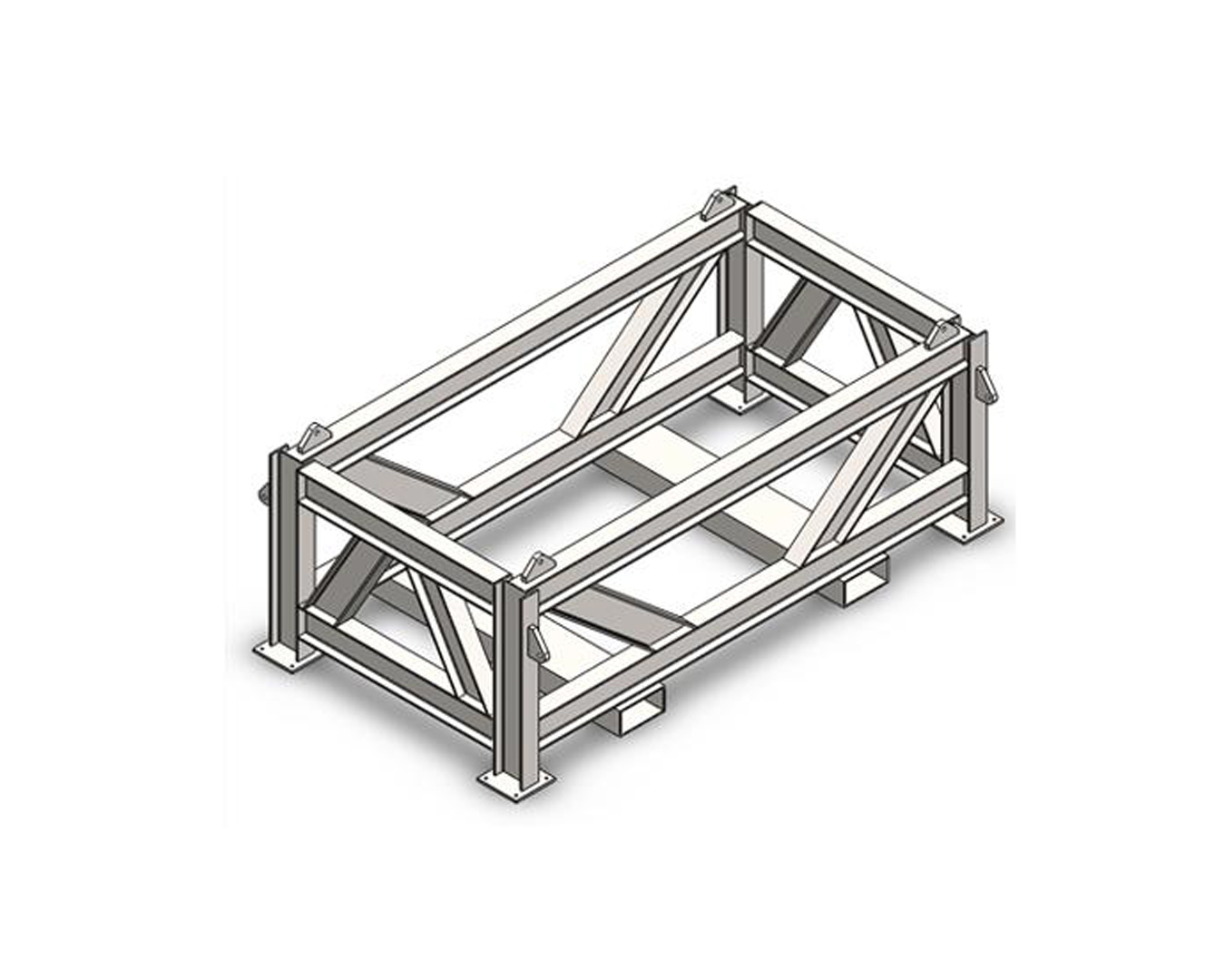

Transport frames and POU's are essential for safe delivery of heavy equipment, yet they’re often treated as “just steelwork”. Designs are rushed late in the project, delegated to general fabrication, and rarely validated against full lifting and transport load cases. The result is inconsistent quality, hidden safety risks, and avoidable rework

If you have transport frames without the following, your assets are at risk:

- Material certification

- Non destructive testing certificates

- Proof load testing documentation

- Maintenance or user instructions

- Nameplates

What We Do

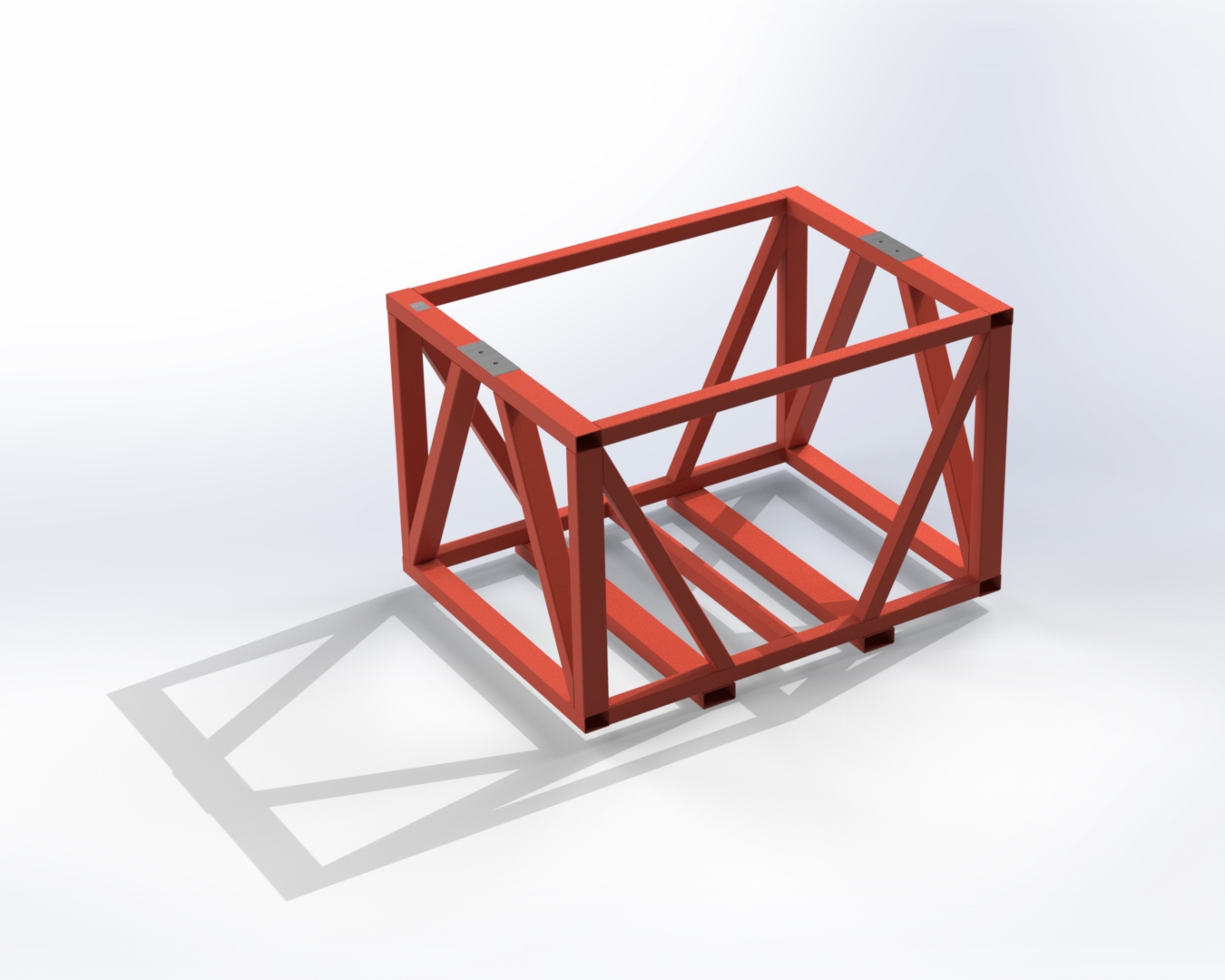

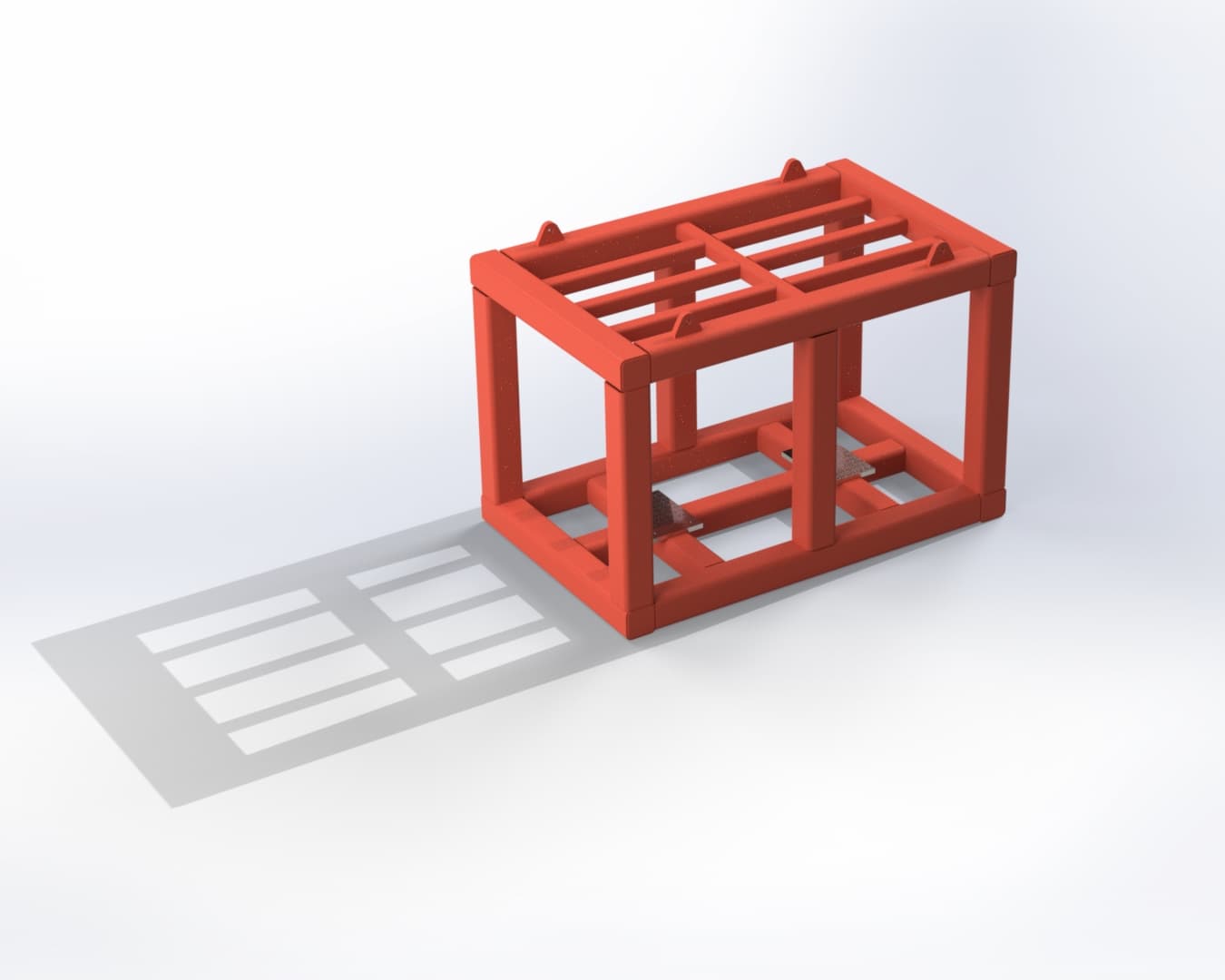

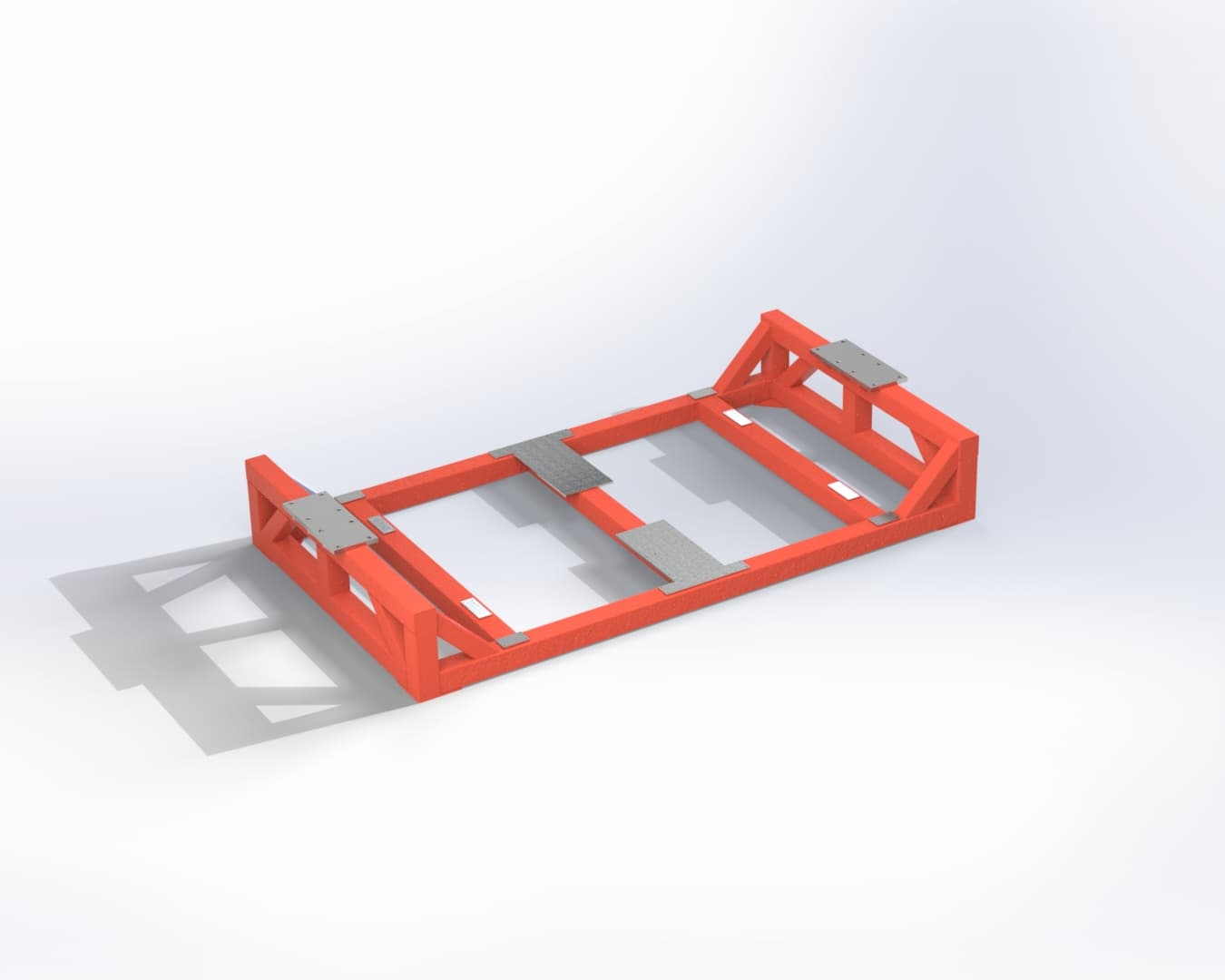

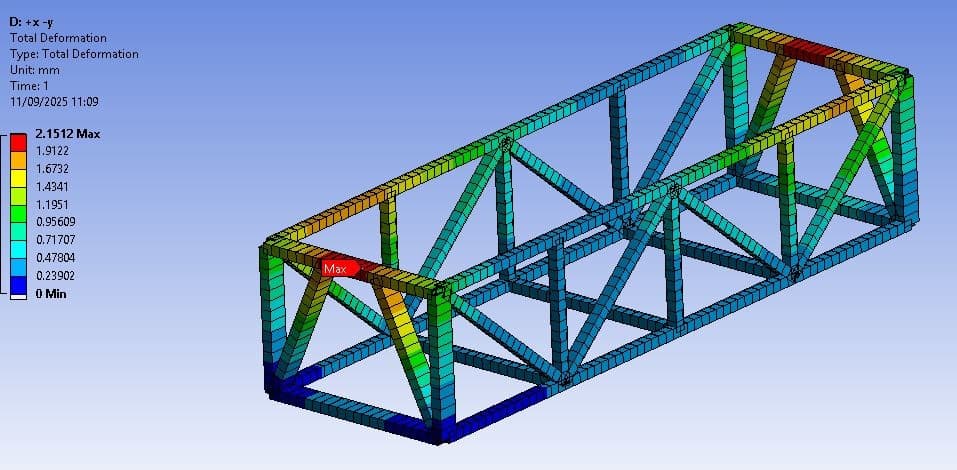

Every frame is engineered to Eurocode 3, ASME and AISC with other codes incorporated if required. We verify stresses, deflection and stability via FEA and hand calculations with transparent load cases and factors of safety.

Where in scope, we supply CE and UKCA marked frames with the correct route to conformity and a complete technical file (Declaration of Conformity/ Incorporation, risk assessment, nameplate, and labelling).

Proof load testing (typically 1.25× WLL) with calibrated rig certificates. Full MRB including drawings, BoM, inspection/NDT, WPS/PQR/WQR, FEA report, CoC, manuals and photos.

We build through a trusted network of heavy steel fabricators, or we can onboard your nominated supplier. Nameplates are durable stainless steel with permanent marking.

We design lifting, lashing and forklift pockets as required, and work with you to ensure the best solution for you and your logistics team.

We supply the following industries:

Oil and Gas

Onshore or offshore we deliver frames which protect vital equipment designed for use in extreme environments such as heat exchangers.

Mining

Our frames ensure critical assets such as drilling equiment arrive safely such as drill heads.

Defence

Frames designed to assist in the movement of large complex equipment, incorporating dunnage to simplify packing requirements.

OEM Parts

Our frames prevent damage to precision made parts so they arrive undamaged and ready to perform.